Molding Is Taking Its Place in Orthopedic Device Manufacturing

As molders continue to expand capabilities attractive to orthopedic device makers, the fabrication process is growing in use.

by Mark Crawford, ODT Contributing Editor | March 19, 2024

Jim Biggs, Director of NPI Technical Solutions at Cretex Medical | CDT, was featured in Orthopedic Design & Technology magazine.

Even with some orthopedic device companies taking a more cautious approach toward R&D, the orthopedic industry remains busy by improving their legacy devices, developing new products, and investing in technology and R&D. Key to much of this steady innovation is the process of injection molding.

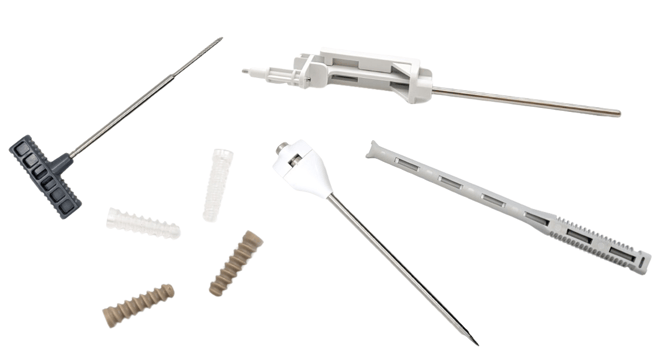

Molding equipment manufacturers and contract manufacturers (CMs) are developing specialized capabilities for producing complex insert-molded assemblies, small to micro-thin wall components with very tight tolerances, and sophisticated value-added assemblies. Orthopedic device manufacturers also have a greater variety than ever before of highly engineered materials from which to choose. For example, screw geometries, once traditionally machined in titanium, can now be molded using alternative materials such as carbon fiber-filled polyether ether ketone (PEEK) and other implant-grade materials. Unique implant geometries that deliver better tissue integration can be molded to fit specific target areas in the body. Bioabsorbable materials are of high interest for molding parts that are eventually absorbed by the body, eliminating the need for multiple-component implants that must be removed at a later date. This latitude gives designers the freedom to add even smaller features to existing geometries at the micro scale to improve performance and functionality.

One reason injection molding is growing so rapidly in the orthopedic industry is its versatility in adapting to mass production. “This, in turn, reduces manufacturing costs,” said Raghu Vadlamudi, chief research and technology director for New Brighton, Mass.-based Donatelle, a medical device contract manufacturer of complex medical devices and components. “For example, because of the reduced manufacturing costs and the consistent quality molding provides, the disposable devices segment of the orthopedic industry is experiencing tremendous growth.”

The miniaturization of devices and components enables ever-expanding minimally invasive surgery (MIS) applications, which typically requires micro molding technologies. For example, “thinner walls, more advanced materials, and complex molding designs are now possible with creative mold-making approaches,” said Lindsay Mann, director of sales and marketing for Charlton, Mass.-based MTD Micro Molding, a manufacturer of ultra-precision, micro-molded components.

As orthopedic devices and components get smaller, molders are constantly developing new and improved methods, techniques, and tools at the micro scale to extend the limits in part design, plastics molding, and speed to market.

What OEMs Want

Orthopedic device manufacturers increasingly expect expert assistance from their CMs in virtually every phase of product design, from inception through design for manufacturing (DFM) to inspection and shipping. They want access to new materials and methods and the expertise that is required to utilize them—for example, the ability to mold with challenging engineering-grade resins in thinner walls and with more challenging geometries. There is a strong demand for components made from PEEK and bioabsorbable components. Ortho companies also expect the highest quality and consistency from lot to lot, without increasing their manufacturing costs.

“OEM needs vary by their unique strategies,” said Jim Biggs, director of NPI Technical Solutions, part of Brooklyn Park, Minn.-based Cretex Medical, which provides high-precision molding services and assembly design for medical devices. Usually, he notes, OEMs are looking for:

-

Up-front and early-in-the-process engineering support

-

DFM recommendations

-

Mold design competency

-

The ability to mold a variety of medical grade and medical implant-grade materials

-

A proven quality management system (QMS) process that satisfies the OEM’s quality and regulatory requirements

Ortho companies are keenly interested in molding bioabsorbable materials, which is currently a hot area of R&D research. Bioabsorbable parts can be used to mitigate tissue trauma and improve patient outcomes. Determining the best bioabsorbable material for an implant involves evaluating different degradation rates. “There is a need to fine-tune the molar ratio of resorbable resins to allow a design to perform an exact function for a specific implantation site,” said Dave Klein, process engineer for MTD Micro Molding. “For example, parts can be made that meet narrow absorption time windows in order to optimize different surgeries.”

Companies want to use the safest materials for their orthopedic products that will reduce the chances of adverse reactions or implant malfunctions. Olefins used in fixation and orthopedic devices, for example, can cause cell and tissue damage—“prompting the need for more biocompatible material alternatives, outside of commodity resins,” said Patrick Haney, R&D engineer for MTD Micro Molding. “Highly engineered biocompatible materials are needed—for example, PEEK is a great material option as it is self-lubricating, strong, and proven in biocompatibility. From an R&D standpoint, this is a hot topic and healthier options for fixation are an ongoing part of the research conversation.”

Of course, there is also the ever-present drive for thinner and smaller features in already miniaturized components, often pushing molding technology to its limits—sometimes resulting in the development of proprietary, in-house molding techniques and solutions based on decades of molding across multiple industries. Ortho companies are especially interested in fitting more capabilities into smaller and more defined envelopes, or making thinner components that are as strong and perform as well as their current thicker components. A top request by OEMs is molding parts from PEEK, including highly filled PEEK, with thinner wall sections and finer features.

“Isometric Micro Molding has successfully molded a PEEK component over 1 inch in length with the thickest wall section being 0.007 inches [175 microns],” said Brent Hahn, vice president and general manager for Isometric Micro Molding, a New Richmond, Wis.-based contract manufacturer that specializes in micro molding and micro automated assembly.

To achieve cost reductions and speed up time to market, ortho companies want their CMs to be as vertically integrated as possible, which shortens the supply chain and accelerates decision-making. With the need for high precision at micro scale, medical device companies and their CMs increasingly work together to optimize manufacturing feasibility and downstream manufacturing steps. “The conversation typically always goes beyond injection molding to include R&D, custom packaging, secondary operations, and testing, with the goal of getting the entire job done with one manufacturer,” said Mann.

How Small Is Small?

It’s typically the first question molders get—how small can they go?

“Early in the design sequence, the team will come to us and ask how small we can make this feature, in this material? And what will it take to move this forward?” said Scott Herbert, president of Pleasanton, Calif.-based Rapidwerks, a provider of micro injection molding services to the medical device industry. “Most requests want features that are 0.005 inches and smaller. However, they sometimes don’t know that the material requested may not achieve the results expected, so they depend on us to find an alternative material that still meets the performance requirements.”

The answer to this question really depends on material and geometry. For example, polymers can behave very differently from one another—some have extreme shrinkage values or higher viscosity than others, which directly influences wall-thickness capabilities. This means that in some polymers, a feature could be 0.001 inches or smaller; in other polymers, the same feature could be 0.012 inches or larger.

“For any specific product,” advised Haney, “OEMs need to have conversations early with their molder to determine feasibility of part and feature size and tolerances for any given polymer. In micro molding, tolerances can be held that will challenge the resolution of even the best measurement equipment. The major concern then is not if the feature or tolerance is possible, but can they be measured consistently and repeatedly.”

Material type is dictated by melt flow and viscosity needs, including the flow length of the material forming the part geometry, wall thickness, and overall geometry, in addition to the gate design approach. “Short flow lengths [for example, 0.035 inches to 0.07 inches] with simple part geometry lend themselves to a variety of medical material options, including PEEK, IXEF [polyarylamide], PCABS [blend of polycarbonate and acrylonitrile butadiene styrene], urethanes, polycarbonates, and polysulfones,” said Biggs. “Longer flow lengths require higher melt flow materials per material specification dictated on material supplier technical data sheets.”

Depending on these parameters, Cretex Medical can produce components with a part weight as low as 0.0005 grams with a wall thickness of 0.003 inches, outside diameter of about 0.05-0.06 inches, and a tolerance of 0.0003-0.0005 inches.

Isometric has been able to successfully mold a part that weighs 0.00004 grams with multiple 75 micron (0.003 inch) wall thicknesses. Isometric has repeatedly achieved a Cpk higher than 1.33 on micro parts that have tolerances of 10 microns or lower.

“With advancements in molding equipment and technologies, it is possible to mold parts as small as a tenth of a milligram in weight and around 30 to 40 microns of wall thicknesses,” added Vadlamudi.

Regardless of how incredibly small a feature can be made, it is worthless if it cannot be measured accurately and reliably.

“We currently mold a part that is so small, the features are difficult to see in plastic, which makes it challenging to measure, even with computed tomography [CT] scanning,” said Maggie Beauregard, quality manager for MTD Micro Molding. “Micro molders must prioritize having the latest advances in metrology equipment and the proper techniques to capture, inspect, and measure the tiniest of part features. "We primarily use OGP scanning equipment, CT scanners, and Keyence microscopes—the method that is utilized depends on a wide range of factors including part size, features to be measured, and material choice/color.”

Advancements and Improvements

Ortho manufacturers and their CMs are using Internet of Things (IoT) and digital technologies to improve their products, especially for process control. Typically, this involves the integration of pressure transducers and sensors into the injection mold and associated injection molding machine. “Data collected using temperature and pressure sensors during the injection molding process, for example, will help in preventing production of defective parts, which in turn, improves the quality of devices,” said Vadlamudi. “Production floor personnel can make better decisions utilizing real-time data available nowadays.”

Artificial intelligence (AI) is already a disruptive technology across a range of industries. Molding techniques for bioabsorbable materials will continue to evolve as AI-assisted research and generative design make new discoveries. AI can be used to rapidly evaluate thousands of potential alloy combinations to find the one that is best for a particular project or product. On the equipment/production side, AI is advancing robot capabilities and is being integrated into inline vision and camera systems on molding and micro molding equipment. “Cameras use AI algorithms to improve the user interface as well as defect and orientation detection,” said Klein. “This translates to automation and robotics that can talk to the vision systems and secondary operations that are performed.”

Robotics and automation are often used in molding manufacturing cells. This enhances the manufacturing process by controlling process repeatability, which greatly reduces cycle time and decreases operator intervention. IoT technologies also make it possible for additive manufacturing (AM) and injection molding to work together to reduce costs and speed up prototyping. In this role, a 3D printer can create proof-of-concept prototypes before the design team invests in the final mold (which can, depending on the project parameters, be built using AM).

TESco Associates, a Tyngsborough, Mass.-based contract manufacturer that specializes in polymer processing techniques and equipment for injection molding, extrusion, and specialty material blending, has been exploring different applications of 3D printing with respect to orthopedic products for some time—especially for prototyping requests from surgeons and researchers for their product designs.

“We utilize additive manufacturing as a form of prototyping for orthopedic devices,” said TESco project engineer Nathan Maynard. “This allows our clients to have a functional part without fronting the high initial price point for injection mold tooling. The materials used for most orthopedic designs are typically not found in the feedstock necessary for additive manufacturing, so specialty equipment is required to process the materials.”

Metal injection molding (MIM) can create many orthopedic components and devices, including surgical tools, implants, drug delivery systems, and orthopedic assistance devices. MIM of mold tooling means shorter tool build lead times, as well as the integration of conformal cooling. This results in faster molding cycle times. Cretex Medical’s 3D metal additive technology includes the laser sintering process for additive materials and an integrated CNC machining center. “This allows for a finished cavity and core that is equivalent to or better than conventional tooling,” said Biggs. “We can perform simulation flow analysis with the Moldex 3D software. Advancements in process control, including eDART and CoPilots, facilitate de-coupled molding.”

Lasers are highly effective in creating complex features and patterns in the mold that add functionality in terms of surface roughness, osseointegration, and antimicrobial capabilities. Lasers can also create micron-sized features within molds, deflash molded ophthalmic implants, and improve osseointegration of injection-molded bioresorbable implants. Although a laser produces incredibly fine features, sometimes the material selected cannot recreate the feature. “There can be limitations in this technology for very small features, but lasers work really well for larger features,” said Herbert. “Also, the ability to create fast samples and try them out is perfect for getting development done quickly and efficiently.”

Sometimes the best improvement in a molding process is not a better technology or material, but finding a way to improve the workflow to be more efficient, such as “combining the molding work cell with other operations such as CNC machining, decorating [pad printing, applying hard coat], ultrasonic welding, and inserting,” said Vadlamudi. “Advances in robotic technology are helping move parts from one piece of equipment to another without human interaction. This helps with consistency and reduced manufacturing costs.”

Continued Innovation

Advanced molding technologies are essential for the production of complex medical-device components made from high-performance materials, which provide exceptional strength and biocompatibility. These molding processes include multi-cavity molds, advanced automation, and in-process quality controls for high-volume production to provide consistent high-quality parts.

Micro molding has already become a go-to technology for the manufacture of orthopedic components and devices and will be an enabling technology for next-generation orthopedic design. As orthopedic devices get smaller and more complex, “it becomes harder for conventional injection molding to make the small intricate details that are required for a part, within the envelopes that are required by most device makers,” said Herbert. With miniaturization, the limitations in subtractive manufacturing processes become more prevalent, forcing engineers to look toward micro molding of plastics and metals.

Especially with orthopedic products, OEM expectations and assumptions tend to default to metal materials. However, more companies are starting to accept plastic materials, which can be equivalent in strength to metal, lighter weight, and just as cost-effective. As they gain deeper knowledge of the advantages of these materials, ortho companies are designing parts specifically for advanced micro molding technology. “This allows molders to get involved sooner and launch molding projects faster,” said Mann. “Orthopedic devices will undoubtedly continue the trend of becoming smaller, more powerful, and less invasive, and micro molding will be the strategic manufacturing solution for higher-volume production.”

Many OEMs are surprised by how the unconventional design and building of molds, when combined with non-traditional and innovative molding practices, can mold orthopedic devices they thought were impossible to make. For example, most injection mold building companies use the tools built into a CAD software package to control and analyze the tooling split process. “On highly complex designs,” said Gary Hulecki, CEO of MTD Micro Molding, “we use mathematical equations to create tooling splits and avoid undercuts. In order to achieve robust and accurate shut-offs on these complex mold components, we create custom fixturing or add features in non-critical areas to control the many different machining processes. With our advanced micro-injection molding process coupled with exact tooling execution, we are able to create the melt, fill the cavity, heat/cool, and de-mold in ways otherwise not thought possible.”

OEMs also tend to assume sensitive materials, such as bioabsorbable materials, cannot be successfully molded—but just the opposite is true. What is critical to success is understanding shear sensitivity. For example, the amount of time a material is exposed to high shear rates is just as important as the level of shear exposure itself. “In micro molding, the time of exposure is extremely fast and, in many cases, the viscoelastic nature of polymers can help to preserve molecular weight,” said Haney. “However, this is not to say that there cannot be consequences to this time of exposure. There is significant evidence that suggests that the process of micro injection has the ability to fundamentally change a material’s microstructure. This is a field of expertise that is rarely explored.”

As micro molding of orthopedic devices continues to advance, molders will be challenged to develop their own improvements, such as narrower process windows, which will require world-class equipment that can produce products reliably and repeatably. Materials, too, will be engineered to facilitate new, miniaturized designs with higher functionality—for example, bioresorbables, fiber-reinforced materials, and higher-flow PEEK materials will all likely enable new applications in ortho products in the near future. Advances in particle size reduction in metal feedstocks will also accelerate device innovations in the orthopedic industry.

IoT will revolutionize the molding industry by improving flexibility and customization and shortening development times. A main goal is the integration of multiple technologies such as AM, molding, and assembly to reduce lead times and provide customized solutions, such as patient-specific devices. Electronics are being developed that can be inserted into very small, molded products for connectivity, remote monitoring, and diagnostic applications. Micro surface finishes that incorporate biomimicry of hydrophobic and hydrophilic surfaces are additional advancements in surface functionality that can be incorporated into micro molding solutions.

Ultimately, molding innovation is driven by digitalization through software advances, digital twins, other simulation or modeling technologies, AI, and IoT. Along the entire product lifecycle—from part design and mold sampling to production, maintenance, and service—these digital technologies will take the art and science of molding processes to next-generation levels.